ENGRAVING

During the engraving process, artwork is etched into a metal plate (die). Then an opaque ink is rolled over the plate and wiped down so that only the ink that has seeped into the crevices of the defined graphic remains. Then a huge amount of pressure is applied to the paper and plate forcing the ink from the plate onto the paper. This process is repeated each time a new color is applied.

COST

Suitable for higher quantities and budgets. Price per unit will decrease as the total quantity increases. Typically not suggested for quantities under 250–500 units unless budget is not a huge factor.

TURNAROUND

Lengthy. 14+ days after proof approval.

PAPER

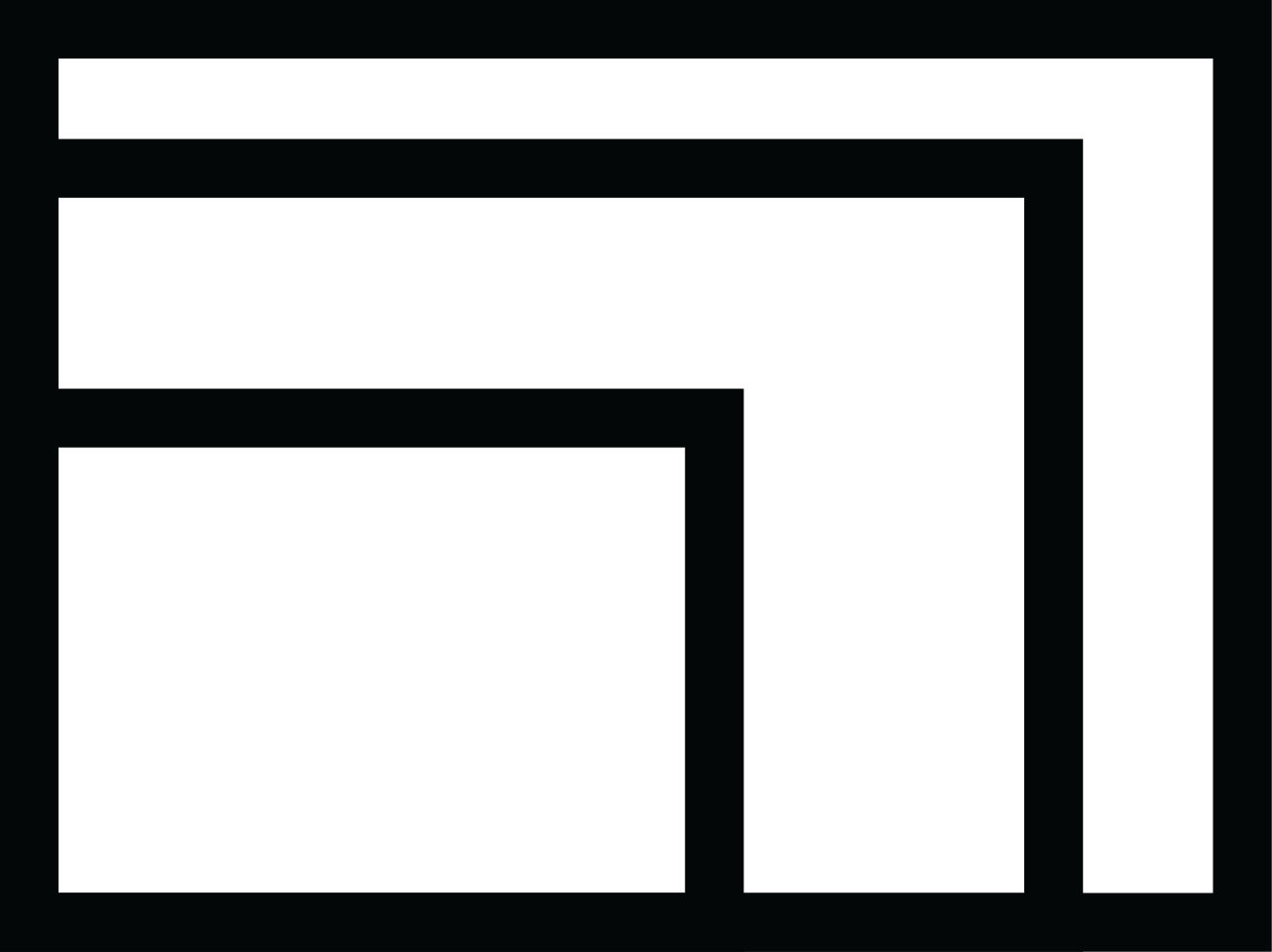

Uncoated papers with higher cotton content work best. Smooth and textured uncoated stocks are also an option, but small details and typography should be avoided on heavily textured stocks. Due to the huge amount of pressure, ultra heavy, cotton-based papers are highly suggested to prevent warping and seeing the slight "ghost" of the outer edges of the rectangular plate.

SHEET SIZE

Maximum artwork size is typically less than 5" x 7". For slightly larger pieces, multiple plates may be used for two passes.

INK

Engraving produces highly opaque and vibrant colors. Therefore, it is a great option when you'd like to print light colors on darker papers. The PMS library of solids and metallics are available for engraving color matches. Similar to letterpress printing, only 1, 2 or 3 ink colors should be used.

DESIGNER INVOLVEMENT

Depending on the relationship with your print shop, they may allow you to review the engraving before the full quantity is completed. If possible, it is recommended that this is done.